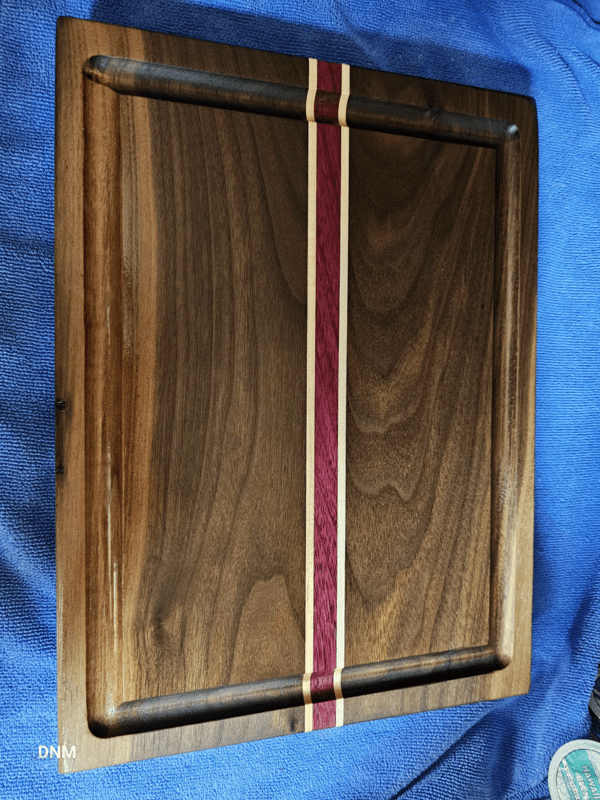

My dental hygienist who had gotten an edge-grain cutting board from me earlier this year wanted a bigger and end-grain one. I went to the wood store to get some Walnut, Hard maple and Purple Heart. I also used some Padauk, Patagonia Rosewood and Canarywood that I already had for the project.

Here are the steps I followed to make the end-grain cutting board. First, I trimmed the boards to 2″ x 26″ x 3/4″. Then, I planed and sanded them with 120 grit sandpaper to ensure a smooth and even surface for gluing. Next, I applied TiteBond III glue to the boards and clamped them together. I left them in the clamps for 48 hours to cure. After that, I planed the glued-up boards again to make them flat. I cut the board into 1.75″ thick slices and arranged them with the end-grain facing up. Finally, I glued and clamped the slices together to form a new board of about 12″ x 18″.

After 2 days in the clamps, the boards were carefully removed and prepared for the next stage of the woodworking process. To ensure a smooth and pristine finish, I opted for a meticulous sanding technique.

To start, I reached for my trusty belt sander fitted with 40-grit sandpaper. This coarse grit allowed me to effectively flatten the boards and eliminate any excess glue squeeze out. Taking my time, I carefully guided the sander across the surface, paying close attention to any uneven areas.

Once I was satisfied with the initial flattening, I progressed to the next step by transitioning to a series of finer grit sandpapers. The goal was to gradually refine the surface, ultimately achieving a flawlessly smooth result. Beginning with 80-grit, I meticulously sanded the boards, ensuring a consistent and even texture.

Moving through the grits, I patiently worked my way up from 80 to 120, then 180, and finally to 220. Each switch in grit allowed me to further refine the surface, gradually eliminating any imperfections. At the 220-grit stage, I decided to “wet” the boards to raise the grain. This technique involved applying a small amount of water to the surface, which caused the wood fibers to swell slightly. Following this, I carefully sanded again using 220-grit sandpaper to achieve a smooth and even texture.

The final touch in the sanding process involved using 320-grit sandpaper. With great attention to detail, I gently went over the boards, ensuring a silky, polished finish. This high-grit sandpaper effectively removed any remaining imperfections, leaving the surface of the boards beautifully refined.

By following this methodical sanding process, I was able to transform the rough boards into stunning pieces ready for the next stages of the woodworking project. The attention to detail and the gradual refinement of the surface made all the difference in achieving the desired end result.

After carefully preparing the boards by sanding and smoothing them, I proceeded to cut the ends at a 25° angle. This angled cut not only adds a touch of style but also makes it easier to handle the boards. To ensure durability and prevent slippage, I attached four Woodkay rubber feet to the bottom of each board. These feet provide stability and protect the surface on which the boards are placed.

To enhance the longevity of the boards, I treated them with food-grade mineral oil. Each board was immersed in the oil bath for 30 minutes, allowing the oil to penetrate deeply into the wood fibers. This nourishing treatment provides optimal protection against moisture and keeps the wood in good condition over time. After the oil bath, the boards were left to sit overnight, allowing the oil to fully soak into the surface of each board.

After carefully drying the boards, it was time to give them the treatment they deserved. With meticulous attention to detail, each board received a lavish application of my exquisite and exclusive Board Butter. This extraordinary concoction comprises a perfect blend of hand-selected oils and waxes, meticulously formulated to provide unrivaled protection and enhance the durability of the wood.

As the silky smooth mixture was delicately spread across the surface of each board, it became apparent that this was no ordinary treatment. The boards seemed to come alive with a renewed vitality, as if they were awakening from a deep slumber.

But the process did not end there. Patience was key, as the boards were left undisturbed overnight, allowing the magical combination of wax and residual oils to seep deeply into the very fibers of the wood. This immersive treatment ensured that every inch of the boards was infused with the goodness of the Board Butter, guaranteeing optimum protection and durability for years to come.

Board Butter Recipe

3- cups food grade mineral oil

1-cup beeswax (white or yellow)

1/4-cup Carnauba wax

Put the mineral oil into a double-boiler over medium heat. Add the waxes to the oil and allow for the waxes to completely melt. Pour the mixture into jars or tins and allow to cool before screwing on lids.

I put each board in a shrink-wrap bag with an envelope that has “Use and Care Instructions”, “What Woods are Used in my Board”, “What is a Butter Board” and a Maidon Woodworking business card. Then I add a tin of Board Butter to the package and start the shrinking process. When the bag is fully shrunk, I have a sealed package ready for the customer.

Wait a minute, what about the scraps of wood left over? Ah, I remember now. So, after I started with a blank 26-inches in length, I carefully cut the blocks to a precise 1.75-inches in length. This process gave me a total of fourteen blocks to work with. But as you may recall, I only needed 10 blocks to create the cutting boards. That meant I had four blocks left over, just sitting there, waiting to be used.

Taking these four left over blocks, I had a brilliant idea. I decided to put them to good use by gluing them together to form a board. This board ended up being approximately 6 inches by 12 inches by 1.75 inches. It was quite a clever way to utilize those remaining blocks and create something useful out of them.

Now, once the glue had been applied and allowed to cure, it was time to further shape these glued blocks. I took them over to the trusty table saw and carefully sawed them in half. This gave me two separate boards from each block, effectively doubling my output. Each of these boards measured approximately 6 inches by 12 inches by 3/4 inches in size. It was remarkable to see how those humble scraps transformed into usable butter boards for future projects.

Of course, like any good woodworker, I wanted to ensure these butter boards were as smooth as possible. So, I took them through the same meticulous sanding process as the cutting boards detailed earlier. It was important to create that seamless finish and ensure that the boards were comfortable to handle.

To add some extra functionality and prevent slippage, I attached rubber feet to the bottom of each butter board. This would provide stability while in use and protect the surfaces they were placed upon.

But the transformation wasn’t complete just yet. I wanted to ensure these butter boards were well-protected and would withstand the test of time. So, I treated them to a nice mineral oil bath. This not only enhanced the natural beauty of the wood but also acted as a protective barrier against moisture and everyday wear and tear.

After each board had been thoroughly dried, it was time to give them the final touch – a generous application of Board Butter. This specially formulated mixture of food-safe oils and beeswax provided a lustrous sheen and further protected the wood from drying out. Plus, it added a touch of elegance to these practical butter boards.

With everything in place, it was time to wrap them up and package them neatly. These finished butter boards were not meant to be sold, but rather, they were gifts for friends and family. It was a way for me to share my craftsmanship and love of woodworking with those closest to me. And I must say, they were truly appreciated by all who received them. It’s always rewarding to see how a simple idea and some leftover scraps can turn into something both functional and meaningful.

So, you see, my friend, that’s the story of how those four leftover blocks found new life as butter boards. It’s a testament to the creativity and resourcefulness that can be found in working with wood.

Why are there eight butter boards instead of the six mentioned above? Earlier this year, I gave all the girls at the dental office I go to a butter board for the great work they do. There were two girls that had started since then. I made two edge-grained butter boards especially for them. The boards were made from Walnut, Padauk and Hard Maple.

Why would I give gifts to the dental assistants, you ask? Well once a year, my dentist provides free dental care to the people of Johnston County that do not have dental insurance and cannot afford dental care. This is why I do what I do.

You must be logged in to submit a review.

One thought on “A Few More Cutting & Butter Boards”